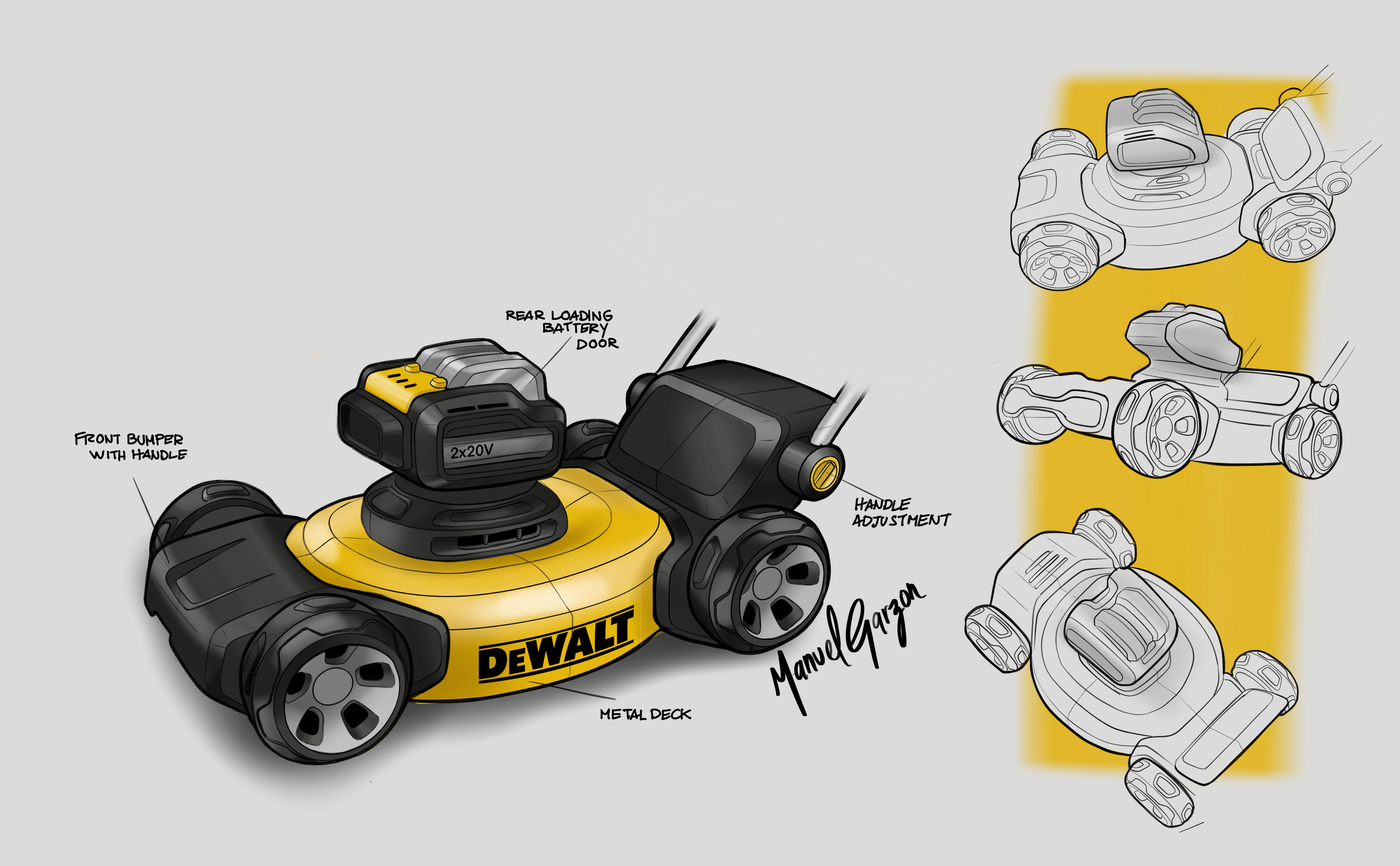

DEWALT electric mower

In the spirit of Raymond Loewy's enduring wisdom—"If your product is surprising, make it familiar; if your product is familiar, make it surprising"—the challenge was to introduce a strikingly innovative electric mower that strikes a delicate balance, marrying novelty with familiarity to ease users' transition from gas to electric power.

Crafted for seamless operation, the batteries are strategically angled for swift replacements, safeguarded by a transparent, water-tight cover that both preserves and highlights their excellence. Every element, from the handles to the controls, has been meticulously honed to guarantee an intuitive and unparalleled mowing experience.

Gravity Sketch VR

Pioneering the use of new VR technology for industrial design during the early days of Gravity Sketch software, initially adopted by the automotive industry in 2018.

Conducting initial exploration and ideation in virtual reality, leveraging engineering components as references to develop cohesive designs and optimize the integration and packaging of internal elements.

User Research

The user is at the heart of the industrial design process. I prioritize visiting users and placing prototypes in their hands to gather direct feedback. The most valuable insights and deepest understanding of a problem come from being out in the field.

Prototypes

Early prototypes designed for ergonomic evaluation, studying handle controls, battery interaction, door mechanism, and battery angle for optimal usability and performance.

Color, Material and Finish (CMF), Initial preproduction samples

Early production samples used to evaluate part fitment and quality, with the first batch produced without textures. Additionally, the translucent door material is assessed to determine the optimal texture and level of transparency.

Branding Artwork exploration

Branding exploration through early concept development in Illustrator, generating multiple design variations for evaluation

Preproduction units

The first batch of preproduction units is assessed, focusing on the fit and quality of parts, as well as the functionality and interactions of moving components. Based on these evaluations, final adjustments are made to ensure readiness for production tooling.

Two versions of the mower were developed: a front-wheel-drive model designed for easier maneuverability on various terrains, and a push model tailored for a more budget-friendly price point and lighter use.

Rendering

Final renders of the completed CAD model were created using KeyShot, showcasing the design in high-quality, photorealistic detail.

Marketing Photography

Professional photography of the final unit, with the user handling it to demonstrate its ergonomic design, ease of use, and interaction with the controls.